I have been thinking about a vacuum plenum for my new Hurricane vacuum system I was going to use MDF but I then decided if I am going to create a vacuum plenum ….. do it right the first time. I decided to use phenolic because it’s stable.

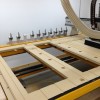

So I had the remove the two layers of MDF that came on the machine. First I had to find the bolts holding the MDF down. In picture 1 you can see in the lower Left hand corner I milled the top layer of MDF off. I then centered my 1/2″ router bit over the first bolts and cut a groove down the Y axis through the first layer reveling bolts (thinking that CAMaster would lay the bolts holes in a pattern) which they did. Once I had the pattern on the X axis and the Y axis I draw the pattern in Aspire, picture number 2. Since I am unable to use the spindle to cut holes at the very back of my spoilboard I used a hand router to remove the top layer of MDF picture 3

Due to the weight of the MDF I decided to cutout sections of the spoilboard between the frame supports, again I used Aspire to draw the cutout cutting all the way through the spoilboard pictures 4 after machining I removed the pieces picture 5, 6 and 7

The new phenolic top should arrive on March 6th ……. I hope

I shall post more when I get the phenolic top.

- Find the bolts holding the spoilboard down

- Bolt pattern drawing Aspire

- Hand routed the rear bolts

- Cutout pattern in Aspire

- 1st section removed

- 2nd section removed

- Bare frame